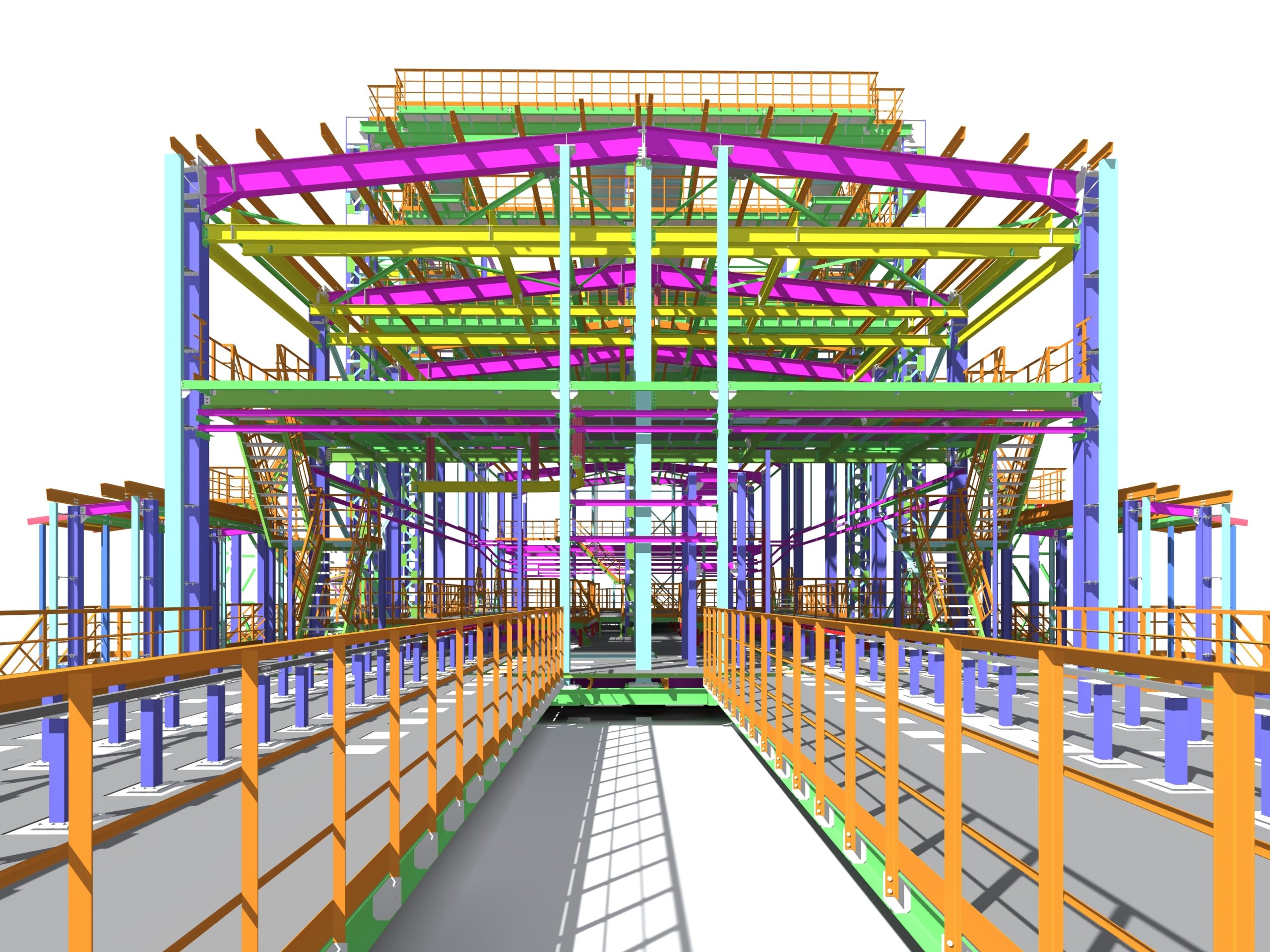

Steel detailing is essential for several reasons in the construction and engineering industry. Steel detailing involves creating detailed drawings and plans for the fabrication and erection of steel structures. Here are some key reasons why steel detailing is considered essential:

1. Accurate Fabrication and Erection: Steel detailing provides precise and detailed information about the components, connections, and dimensions of a steel structure. This ensures that the steel components are fabricated and erected accurately, minimizing errors and rework during construction.

2. Safety: Proper steel detailing helps ensure the safety of the structure, workers, and occupants. Detailed drawings provide information about load distribution, connection types, and other critical aspects that contribute to the structural integrity and safety of the building.

3. Cost-Efficiency: Accurate steel detailing helps reduce material wastage and construction delays. When steel components are fabricated according to precise specifications, there is less likelihood of errors, which can lead to costly revisions and delays.

4. Efficient Construction: Well-detailed steel plans and drawings streamline the construction process. Contractors and workers can understand the design intent more easily, leading to smoother collaboration and faster construction progress.

5. Coordination: Steel detailing involves coordination with other disciplines, such as architectural and mechanical engineering. This coordination ensures that steel components integrate seamlessly with other building systems, such as HVAC, plumbing, and electrical.

6. Clash Detection: Detailed steel drawings allow for clash detection, identifying potential conflicts between different building systems early in the design process. This helps prevent costly and time-consuming clashes during construction.

7. Compliance: Steel detailing ensures that the structure complies with relevant building codes, regulations, and industry standards. This is crucial for obtaining necessary permits and approvals from regulatory authorities.

8. Visualization: Detailed drawings provide a visual representation of the final steel structure. This helps stakeholders, including architects, engineers, contractors, and clients, better understand the design and make informed decisions.

9. Quality Assurance: Steel detailing involves a thorough review process to check for accuracy and completeness. This quality assurance process helps identify and rectify potential issues before construction begins.

10. Documentation: Detailed steel drawings serve as a valuable source of documentation for the project. They provide a record of the design intent, which can be referenced during construction, maintenance, and future renovations.

In summary, steel detailing plays a crucial role in ensuring the accuracy, safety, efficiency, and overall success of steel construction projects. It helps bridge the gap between design and construction, facilitating effective communication and collaboration among various stakeholders involved in the project.